ABB, as an expert in electrical problem solving, participated in the 2024 Yipaike Industrial Products Exhibition and the Petroleum and Petrochemical Industry Exhibition

ABB provides end-to-end sustainable medium and low voltage distribution systems and full lifecycle services to meet the electrical needs of various application scenarios in the upstream, midstream, and downstream of the petroleum and petrochemical industry

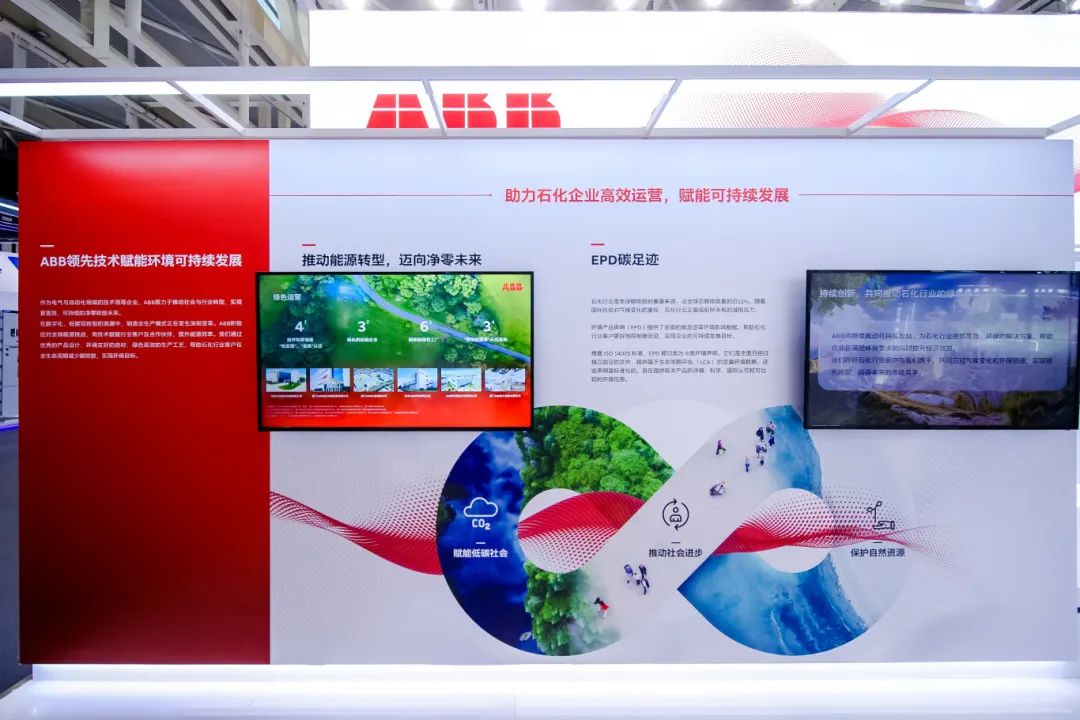

Based on excellent product design, environmentally friendly material selection, and green and efficient production processes, ABB helps customers save carbon emissions throughout their entire lifecycle

Green and low-carbon is an important direction for the transformation and upgrading of China’s petroleum and petrochemical industry. It is necessary to promote breakthroughs in key technologies and technological achievements of new green chemical industry, accelerate the development of new quality productivity, and promote revolutionary changes in the energy sector. At the 2024 Yipaike Industrial Products Exhibition and Petroleum and Petrochemical Industry Exhibition held from October 11th to 13th, ABB, as an expert in electrical problem solving in the petroleum and petrochemical industry, showcased its innovative medium and low voltage distribution and service solutions, demonstrating its full scenario low-carbon product capabilities that run through solution design, project construction, system operation, and lifecycle maintenance, helping petrochemical enterprises ensure continuous and stable production processes, achieve cost reduction and efficiency improvement, and empower sustainable development.

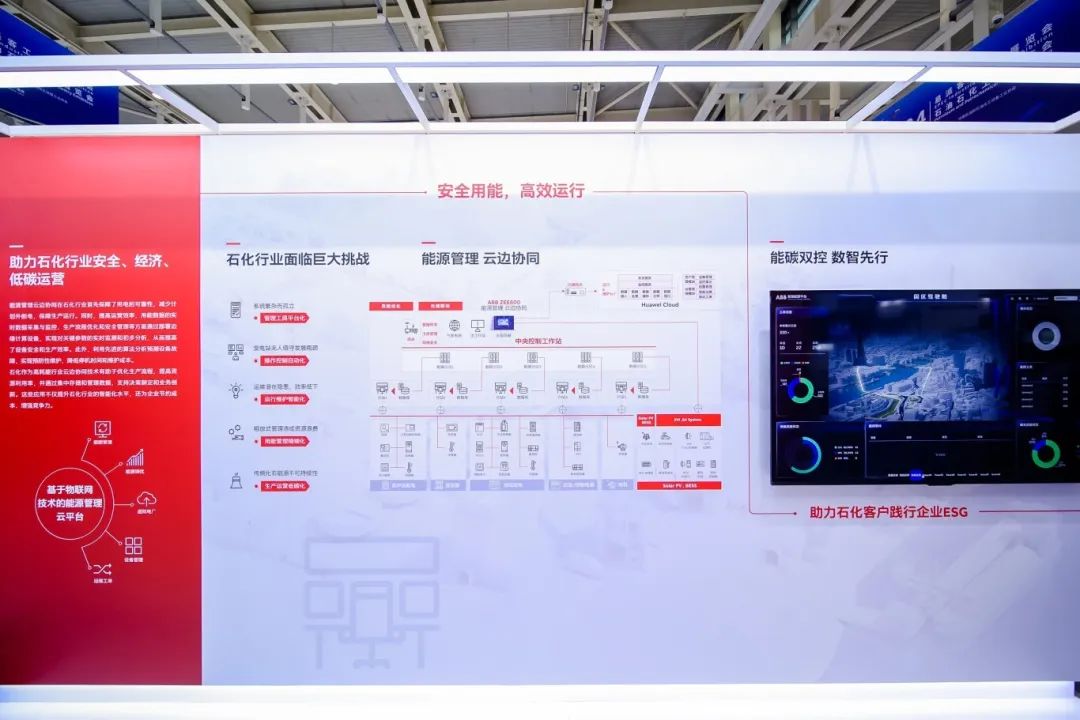

At present, various petrochemical enterprises are vigorously implementing energy conservation and emission reduction, as well as clean energy substitution for production, to reduce fossil energy consumption and carbon dioxide emissions from the source. Faced with numerous problems faced by industry enterprises, such as complex and isolated systems, low operation and maintenance efficiency, extensive management, and the unsustainability of traditional energy, there is an urgent need for an energy management “brain” to timely, accurately, intelligently, and flexibly address these issues.

The ABB Smart Energy Carbon Management Platform is an energy management cloud platform based on IoT technology. The functions of this “central processor” include energy carbon management, energy optimization, virtual power plants, equipment management, and operation and maintenance work orders. Firstly, with the integration of more clean energy sources, ensure the reliability of electricity consumption, reduce unplanned power outages, and guarantee production operations. At the same time, the operation efficiency is improved. In terms of real-time data collection and monitoring of energy consumption data, production process optimization and security management, edge computing equipment is deployed to realize real-time monitoring and preliminary analysis of key parameters, thus improving equipment safety and production efficiency. In addition, advanced algorithms are used to analyze and predict equipment failures, achieve predictive maintenance, and reduce downtime and maintenance costs.

Reliable and stable medium and low voltage distribution equipment is the underlying guarantee of the “brain” of energy management. Due to the continuity and high degree of automation in the production process of petroleum and petrochemicals, any power failure or power quality issue may lead to serious safety hazards and economic losses. ABB provides time proven power supply safety and power quality solutions to help petrochemical companies ensure the stability and efficiency of their power systems, safeguarding their safe production.

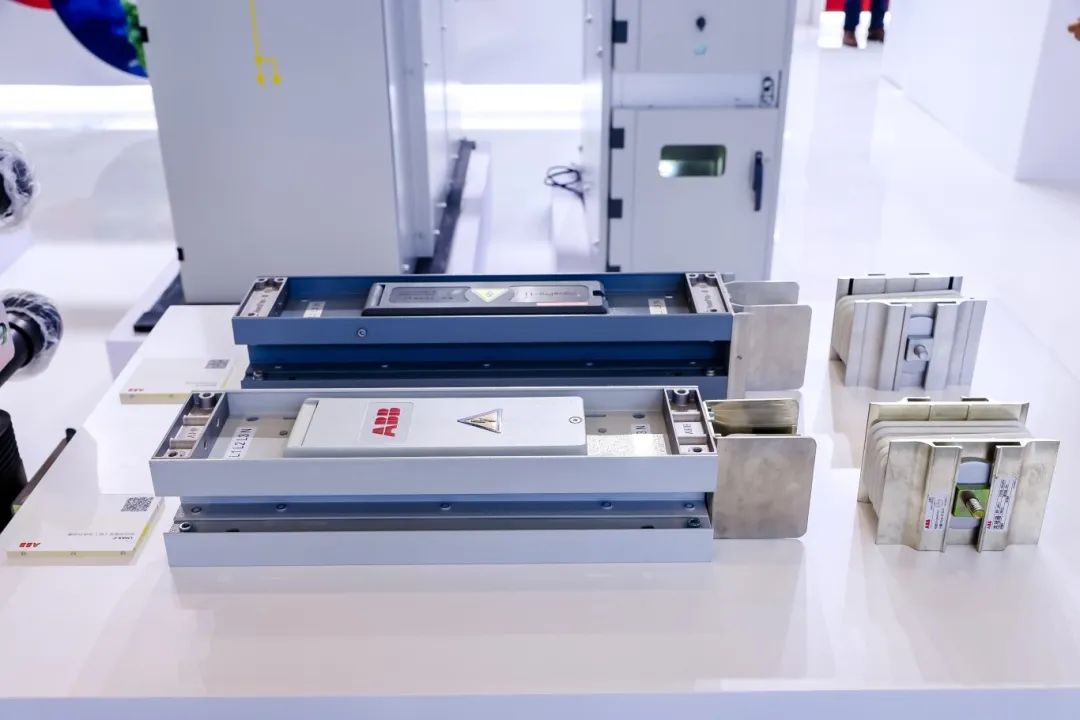

At the exhibition site, ABB showcased modular, diversified, and high-quality electrical equipment, such as UniGear ZS1 500mm cabinet width medium voltage switchgear, ZX2 medium voltage switchgear, iVD4 medium voltage intelligent circuit breaker, MNS Digital low voltage switchgear, WavePro series bus duct, PowerCare worry free operation and maintenance services, OneFit ® replacement service products, etc.

Among them, the star product displayed, UniGear ZS1 500mm cabinet wide medium voltage switchgear, was born in 2019 and is currently ABB’s narrowest mid mounted switchgear. This year marks the 25th anniversary of ABB’s launch of UniGear switchgear. Over the past 25 years, this product series has installed more than 700000 units worldwide, ensuring the continuity, reliability, and safety of electricity consumption in many key industries, including the petroleum and petrochemical industry, with high reliability and technological leadership, and helping to meet the growing demand for sustainable development.

The MNS Digital switchgear inherits the leading quality standards and manufacturing processes of the MNS system, combining intelligent devices with data interfaces to transform traditional preventive maintenance into predictive maintenance. Integrating ABB low-voltage switchgear operation monitoring system, customers can real-time understand the operation status and equipment health status of low-voltage switchgear. Based on big data learning and mechanism models, equipment health artificial intelligence algorithms can achieve forward-looking maintenance, greatly improving maintenance efficiency and meeting the safe, reliable, and sustainable electricity needs of users in the petrochemical industry. This year marks the 30th anniversary of the establishment of ABB Low Voltage Electrical Equipment Co., Ltd. in Xiamen. ABB will continue to focus on innovation and provide protection for customers’ safety production.

The ABB WavePro series low-voltage dense bus duct is a complete set of equipment used for transmitting and distributing electrical energy in low-voltage distribution systems. It has the advantages of high current carrying capacity, high protection level, convenient distribution of electrical energy, safety and reliability. These two bus duct products will further improve the electrification rate of the energy system and provide reliable support for the utilization of clean energy.

In order to better assist enterprises in achieving environmental goals, ABB is committed to helping customers save carbon emissions throughout the entire lifecycle through excellent product design, environmentally friendly material selection, and green and efficient production processes. It also provides comprehensive information disclosure on the environmental impact of products throughout their lifecycle, helping petroleum and petrochemical customers better control their carbon footprint.

Leave a comment

Your email address will not be published. Required fields are marked *